Table of Contents

- Introduction

- The Innovative Idea

- Environmental Benefits

- Economic Impact

- Technical Process

- Community and Government Response

- Future Prospects

- Conclusion

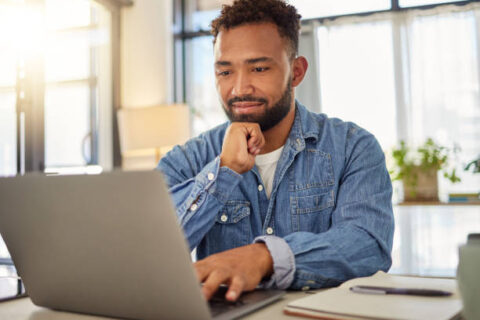

Introduction

In a groundbreaking initiative, a Pakistani man has begun manufacturing bricks from plastic trash. This innovative approach not only tackles the pressing issue of plastic waste but also offers a sustainable building material for construction purposes.

The Innovative Idea

The man behind this initiative recognized the potential of transforming plastic waste into useful construction materials. By collecting plastic trash and converting it into bricks, he is addressing two significant issues: the mounting plastic waste problem and the demand for affordable building materials.

Environmental Benefits

The environmental benefits of this initiative are substantial:

- Reduction of Plastic Waste: By diverting plastic trash from landfills and oceans, the initiative helps reduce pollution and its detrimental effects on wildlife and ecosystems.

- Sustainable Construction: The plastic bricks provide a sustainable alternative to traditional building materials, which often require extensive natural resources and energy to produce.

- Lower Carbon Footprint: The production of plastic bricks emits less carbon dioxide compared to conventional brick manufacturing, contributing to the fight against climate change.

Economic Impact

This innovative solution also has promising economic implications:

- Job Creation: The process of collecting, processing, and manufacturing plastic bricks generates employment opportunities, particularly in waste management and construction sectors.

- Cost-Effective Housing: The affordability of plastic bricks can make housing more accessible to low-income communities, addressing housing shortages and improving living conditions.

- Revenue Generation: The sale of plastic bricks can generate income for small businesses and entrepreneurs, stimulating local economies.

Technical Process

The technical process of creating plastic bricks involves several steps:

- Collection: Plastic waste is collected from various sources, including households, businesses, and public spaces.

- Sorting and Cleaning: The collected plastic is sorted by type and thoroughly cleaned to remove any contaminants.

- Shredding and Melting: The clean plastic is shredded into small pieces and then melted down.

- Molding: The melted plastic is poured into brick molds and allowed to cool and harden.

- Quality Control: The finished bricks undergo quality control checks to ensure they meet the necessary standards for construction use.

Community and Government Response

The community has shown significant support for this eco-friendly initiative. Many locals have started participating in plastic waste collection efforts, contributing to the project’s success. Additionally, the government has taken notice and is exploring ways to support and scale up this innovative solution through policies and incentives.

Future Prospects

The future prospects of this initiative are promising:

- Scaling Up: There are plans to expand the production of plastic bricks to other regions, increasing their availability and impact.

- Innovations: Continuous research and development efforts aim to improve the quality and durability of the plastic bricks, making them suitable for a wider range of construction applications.

- Global Influence: This initiative has the potential to inspire similar projects worldwide, promoting sustainable construction practices and waste management solutions globally.

Conclusion

The initiative to build bricks from plastic trash in Pakistan is a remarkable example of innovation addressing environmental and economic challenges. By transforming plastic waste into sustainable building materials, this project offers a solution that benefits the environment, the economy, and the community. As the initiative progresses, it holds the promise of significantly impacting waste management and construction practices both locally and globally.